Bending Process | AMADA Fiber-Laser & CNC Bending - Siang Hsing

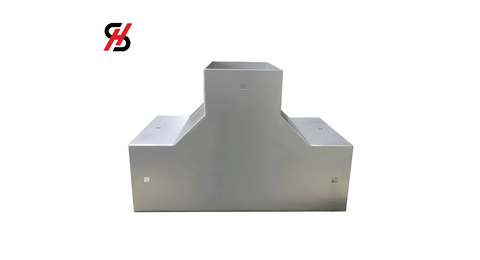

The AMADA Hydraulic Hybrid Press Brake is utilized to bend flat metal sheets into various shapes and structures. This advanced equipment is renowned for its high precision and efficiency, making it applicable in manufacturing components across diverse industries. See all Siang Hsing products—high‑precision metal enclosures, cabinets, frames, and functional components. AMADA fiber laser cutting + CNC bending + welding + finishing for reliable results.

Bending Process

Sheet Metal Bending, Bending & Forming

The AMADA Hydraulic Hybrid Press Brake is utilized to bend flat metal sheets into various shapes and structures. This advanced equipment is renowned for its high precision and efficiency, making it applicable in manufacturing components across diverse industries.

Features

- Side frame distance: 3760mm

- Bending Length: 4300mm

- Pressing Capacity: 2200kN

- Tracking Device: SF-1224TL

- Angle Detector: Bi-S Connection Type

- 1 Axis – 50KG; 2 Axes – 100KG

- Maximum processing size: 1000*2000mm

- Servo-hydraulic: Utilizes servo control technology to drive the hydraulic system for more efficient and precise operation.

- Hybrid Press Brake: Capable of performing various bending operations, suitable for sheet metal processing of different thicknesses and types.

- Machine

Bending Process | Siang Hsing (SHPS)

Siang Hsing Precision Stamping Co., Ltd. is a local professional metal processing product manufacturer in Taiwan. Established in 2023, the founder has over 28 years of experience in precision machining, sheet metal processing, surface treatment, welding, laser cutting, workpiece assembly, and bending operations. Siang Hsing (SHPS) consistently meets the various quality requirements of its customers.

One-stop Bending Process - Siang Hsing (SHPS) delivers precise sheet metal fabrication through high-accuracy laser cutting, CNC bending, welding, and assembly. Our streamlined workflow ensures clean edges, accurate forming, and dependable quality for custom enclosures, brackets, frames, and industrial components across multiple industries.