Workpiece Assembly Service | AMADA Fiber-Laser & CNC Bending - Siang Hsing

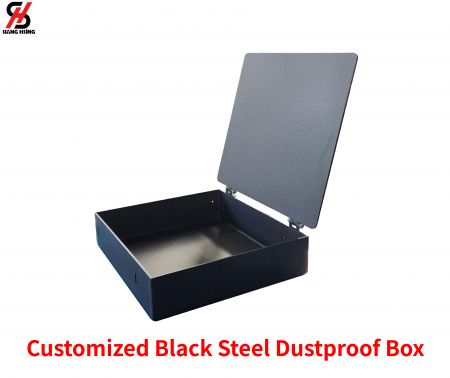

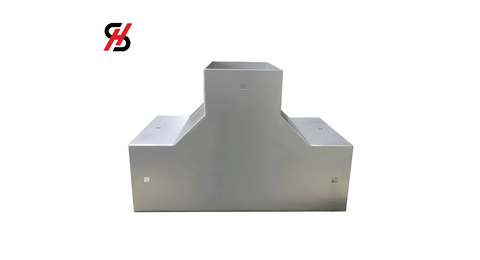

Siang Hsing provides customized workpieces based on customer requirements. Sheet metal undergoes processing such as cutting, bending, and welding, followed by assembly into final parts or products. Our precision sheet metal solutions are widely applied across various industries, including industrial machinery, electrical control cabinets, precision metal parts, a wide range of casings and enclosures, components for engineering projects, mechanical housing frames, medical equipment, and food processing machinery. See all Siang Hsing products—high‑precision metal enclosures, cabinets, frames, and functional components. AMADA fiber laser cutting + CNC bending + welding + finishing for reliable results.

Workpiece Assembly Service

Contract Assembly, Customization, Sheet Metal Fabrication, Welding

Siang Hsing provides customized workpieces based on customer requirements. Sheet metal undergoes processing such as cutting, bending, and welding, followed by assembly into final parts or products. Our precision sheet metal solutions are widely applied across various industries, including industrial machinery, electrical control cabinets, precision metal parts, a wide range of casings and enclosures, components for engineering projects, mechanical housing frames, medical equipment, and food processing machinery.

Features

- Customization is available according to customer requirements

- Application Fields: Industrial machinery, electrical control boxes, precision sheet metal components, various housings and covers, engineering project parts, machine enclosures and frames, medical equipment, and food machinery.

Workpiece Assembly Service | Siang Hsing (SHPS)

Siang Hsing Precision Stamping Co., Ltd. is a local professional metal processing product manufacturer in Taiwan. Established in 2023, the founder has over 28 years of experience in precision machining, sheet metal processing, surface treatment, welding, laser cutting, workpiece assembly, and bending operations. Siang Hsing (SHPS) consistently meets the various quality requirements of its customers.

One-stop Workpiece Assembly Service - Siang Hsing (SHPS) delivers precise sheet metal fabrication through high-accuracy laser cutting, CNC bending, welding, and assembly. Our streamlined workflow ensures clean edges, accurate forming, and dependable quality for custom enclosures, brackets, frames, and industrial components across multiple industries.