Final Product Quality Control | Welding, Forming & Post-Processing - Siang Hsing

At Siang Hsing, we strictly control product quality to ensure full compliance with quality standards and specification requirements. Our thorough inspection processes help prevent defective spare parts from entering the production line, improving overall product yield and ensuring consistent product reliability. Browse Siang Hsing product categories: fiber laser cutting, high-precision bending, welding, forming & post-processing. One-stop sheet metal service for complex parts, fast lead times & strict QC.

Final Product Quality Control

Product Inspection, Incoming Quality Control (IQC), In Process Quality Control (IPQC), Final Quality Control (FQC), Outgoing Quality Control (OQC)

At Siang Hsing, we strictly control product quality to ensure full compliance with quality standards and specification requirements. Our thorough inspection processes help prevent defective spare parts from entering the production line, improving overall product yield and ensuring consistent product reliability.

The Quality Control Inspection Process is illustrated below:

Siang Hsing has been officially certified as a Digital Sheet Metal Fabrication Manufacturer, enabling us to ensure precision and process stability through standardized procedures and intelligent manufacturing systems.

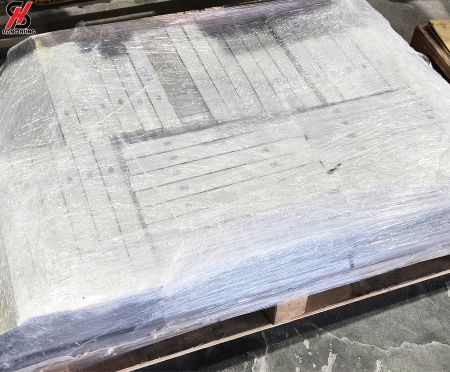

Incoming Quality Control

Incoming Quality Control (IQC) serves as the first checkpoint in the quality management process....

DetailsIn Process Quality Control

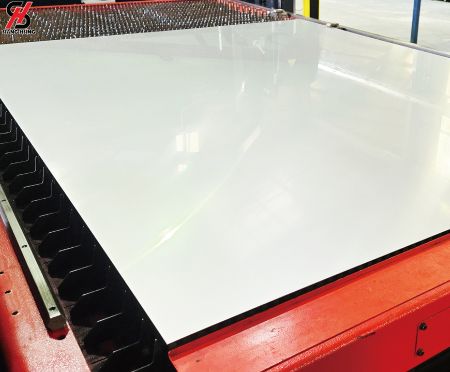

In-Process Quality Control (IPQC) involves real-time sampling inspection and monitoring at key stages...

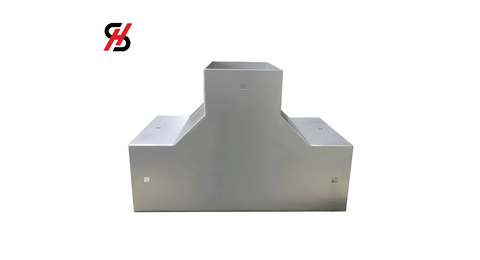

DetailsFinal Quality Control

Final Quality Control (FQC) serves as the final checkpoint in the quality management process....

DetailsOutgoing Quality Control

Outgoing Quality Control (OQC) – Shipment Verification is the final inspection step Siang...

DetailsFinal Product Quality Control | Sheet Metal Fabrication Services - Siang Hsing

Siang Hsing Precision Stamping Co., Ltd. is a local professional metal processing product manufacturer in Taiwan. Established in 2023, the founder has over 28 years of experience in precision machining, sheet metal processing, surface treatment, welding, laser cutting, workpiece assembly, and bending operations. Siang Hsing (SHPS) consistently meets the various quality requirements of its customers.

One-stop Final Product Quality Control - Siang Hsing (SHPS) delivers precise sheet metal fabrication through high-accuracy laser cutting, CNC bending, welding, and assembly. Our streamlined workflow ensures clean edges, accurate forming, and dependable quality for custom enclosures, brackets, frames, and industrial components across multiple industries.