Outgoing Quality Control | AMADA Fiber-Laser & CNC Bending - Siang Hsing

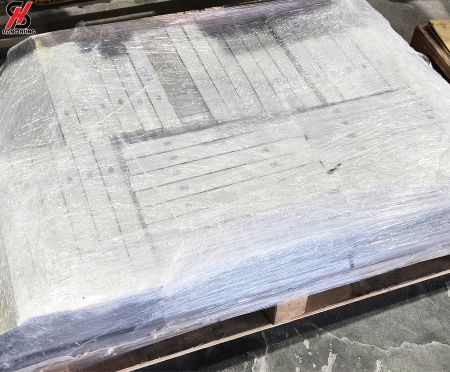

Outgoing Quality Control (OQC) – Shipment Verification is the final inspection step Siang Hsing performs before products are officially packed and shipped. This process ensures all products meet internal standards as well as customer requirements regarding packaging, labeling, quantity, and appearance.

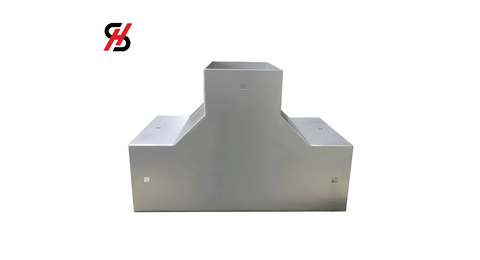

Key checks include verifying packaging integrity, confirming product quantity, and conducting stricter inspections for specific customer demands. See all Siang Hsing products—high‑precision metal enclosures, cabinets, frames, and functional components. AMADA fiber laser cutting + CNC bending + welding + finishing for reliable results.

Outgoing Quality Control

OQC, Delivery, Packaging, Verification

Outgoing Quality Control (OQC) – Shipment Verification is the final inspection step Siang Hsing performs before products are officially packed and shipped. This process ensures all products meet internal standards as well as customer requirements regarding packaging, labeling, quantity, and appearance.

Key checks include verifying packaging integrity, confirming product quantity, and conducting stricter inspections for specific customer demands.

Outgoing Quality Control | Siang Hsing (SHPS)

Siang Hsing Precision Stamping Co., Ltd. is a local professional metal processing product manufacturer in Taiwan. Established in 2023, the founder has over 28 years of experience in precision machining, sheet metal processing, surface treatment, welding, laser cutting, workpiece assembly, and bending operations. Siang Hsing (SHPS) consistently meets the various quality requirements of its customers.

One-stop Outgoing Quality Control - Siang Hsing (SHPS) delivers precise sheet metal fabrication through high-accuracy laser cutting, CNC bending, welding, and assembly. Our streamlined workflow ensures clean edges, accurate forming, and dependable quality for custom enclosures, brackets, frames, and industrial components across multiple industries.