In Process Quality Control | AMADA Fiber-Laser & CNC Bending - Siang Hsing

In-Process Quality Control (IPQC) involves real-time sampling inspection and monitoring at key stages of the manufacturing process. Key inspection items include dimensions, tolerances, functionality, structural integrity, and surface defects, all evaluated according to standard operating procedures (SOP) or inspection criteria.

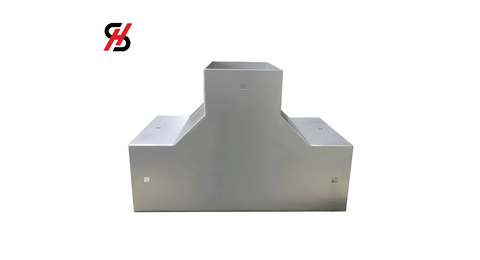

Through continuous process monitoring and data recording, IPQC promptly detects abnormalities and provides immediate feedback to adjust manufacturing parameters or methods. This prevents defect escalation and batch failures, ensures stable product quality, improves overall manufacturing efficiency, and reduces rework costs. IPQC is a vital part of Siang Hsing's quality management system. See all Siang Hsing products—high‑precision metal enclosures, cabinets, frames, and functional components. AMADA fiber laser cutting + CNC bending + welding + finishing for reliable results.

In Process Quality Control

IPQC, Inspection, Sampling Inspection

In-Process Quality Control (IPQC) involves real-time sampling inspection and monitoring at key stages of the manufacturing process. Key inspection items include dimensions, tolerances, functionality, structural integrity, and surface defects, all evaluated according to standard operating procedures (SOP) or inspection criteria.

Through continuous process monitoring and data recording, IPQC promptly detects abnormalities and provides immediate feedback to adjust manufacturing parameters or methods. This prevents defect escalation and batch failures, ensures stable product quality, improves overall manufacturing efficiency, and reduces rework costs. IPQC is a vital part of Siang Hsing's quality management system.

In Process Quality Control | Siang Hsing (SHPS)

Siang Hsing Precision Stamping Co., Ltd. is a local professional metal processing product manufacturer in Taiwan. Established in 2023, the founder has over 28 years of experience in precision machining, sheet metal processing, surface treatment, welding, laser cutting, workpiece assembly, and bending operations. Siang Hsing (SHPS) consistently meets the various quality requirements of its customers.

One-stop In Process Quality Control - Siang Hsing (SHPS) delivers precise sheet metal fabrication through high-accuracy laser cutting, CNC bending, welding, and assembly. Our streamlined workflow ensures clean edges, accurate forming, and dependable quality for custom enclosures, brackets, frames, and industrial components across multiple industries.