Laser-Cutting Services | AMADA Fiber-Laser & CNC Bending - Siang Hsing

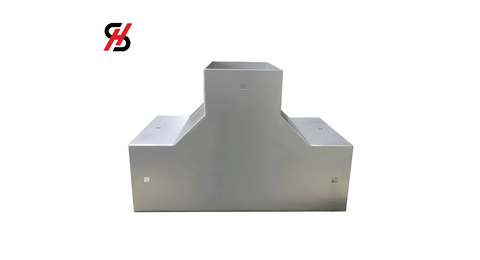

Utilizing an advanced AMADA fiber laser cutting machine, Siang Hsing delivers high-precision cutting by focusing a powerful laser beam on the material surface—ideal for a wide range of sheet metal fabrication needs. After cutting, any minor burrs or slag along the edges are removed through treatments such as deburring or edge grinding, enhance surface finish, improve safety, and ensure flawless assembly and downstream processing. See all Siang Hsing products—high‑precision metal enclosures, cabinets, frames, and functional components. AMADA fiber laser cutting + CNC bending + welding + finishing for reliable results.

Laser-Cutting Services

Sheet Metal Cutting, Laser Cutting, Laser Marking, Deburring

Utilizing an advanced AMADA fiber laser cutting machine, Siang Hsing delivers high-precision cutting by focusing a powerful laser beam on the material surface—ideal for a wide range of sheet metal fabrication needs. After cutting, any minor burrs or slag along the edges are removed through treatments such as deburring or edge grinding, enhance surface finish, improve safety, and ensure flawless assembly and downstream processing.

Features

- High-Efficiency Cutting: The Fiber Laser Cutting Machine delivers high-power beams for fast and precise cutting, enabling high-accuracy results and reduced processing time.

- High Precision: Delivers exceptional accuracy for complex lines and shapes, making it ideal for precision manufacturing.

- Multi-Material Capacity: Effectively process a wide range of metals, such as stainless steel, aluminum (Al), copper (Cu), brass, etc., and maintain strong cutting performance even at greater thicknesses of material.

- Eco-Friendly & Energy Efficient: Fiber laser systems generate minimal thermal distortion, smoke, and noise. The system’s energy-efficient design significantly reduces power consumption compared to the traditional laser cutting method.

- Machine

Laser-Cutting Services | Siang Hsing (SHPS)

Siang Hsing Precision Stamping Co., Ltd. is a local professional metal processing product manufacturer in Taiwan. Established in 2023, the founder has over 28 years of experience in precision machining, sheet metal processing, surface treatment, welding, laser cutting, workpiece assembly, and bending operations. Siang Hsing (SHPS) consistently meets the various quality requirements of its customers.

One-stop Laser-Cutting Services - Siang Hsing (SHPS) delivers precise sheet metal fabrication through high-accuracy laser cutting, CNC bending, welding, and assembly. Our streamlined workflow ensures clean edges, accurate forming, and dependable quality for custom enclosures, brackets, frames, and industrial components across multiple industries.