Rolling Process | AMADA Fiber-Laser & CNC Bending - Siang Hsing

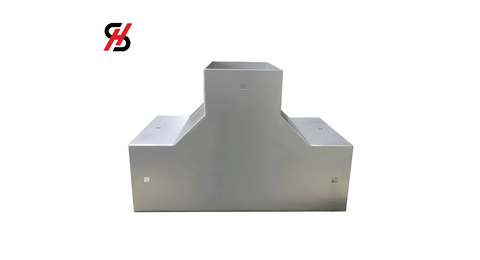

Siang Hsing offers professional sheet metal rolling services, transforming flat sheet materials into circular, curved, or cylindrical shapes based on customer requirements. This process is commonly used for fabricating industrial components such as tanks, ducts, and cylindrical housings.

We work closely with clients to handle sheets of various materials and thicknesses, ensuring precise dimensions and uniform curvature. Combined with our welding, assembly, and surface treatment capabilities, we provide a complete, end-to-end fabrication solution. See all Siang Hsing products—high‑precision metal enclosures, cabinets, frames, and functional components. AMADA fiber laser cutting + CNC bending + welding + finishing for reliable results.

Rolling Process

Sheet Metal Rolling, Rolling Process, Machining Services

Siang Hsing offers professional sheet metal rolling services, transforming flat sheet materials into circular, curved, or cylindrical shapes based on customer requirements. This process is commonly used for fabricating industrial components such as tanks, ducts, and cylindrical housings.

We work closely with clients to handle sheets of various materials and thicknesses, ensuring precise dimensions and uniform curvature. Combined with our welding, assembly, and surface treatment capabilities, we provide a complete, end-to-end fabrication solution.

Rolling Process | Siang Hsing (SHPS)

Siang Hsing Precision Stamping Co., Ltd. is a local professional metal processing product manufacturer in Taiwan. Established in 2023, the founder has over 28 years of experience in precision machining, sheet metal processing, surface treatment, welding, laser cutting, workpiece assembly, and bending operations. Siang Hsing (SHPS) consistently meets the various quality requirements of its customers.

One-stop Rolling Process - Siang Hsing (SHPS) delivers precise sheet metal fabrication through high-accuracy laser cutting, CNC bending, welding, and assembly. Our streamlined workflow ensures clean edges, accurate forming, and dependable quality for custom enclosures, brackets, frames, and industrial components across multiple industries.