Sheet Metal Processing Scope | AMADA Fiber-Laser & CNC Bending - Siang Hsing

Siang Hsing specializes in precision processing of stainless steel, black steel, aluminum, copper, other metals, meeting a wide range of structural and mechanical applications needs.

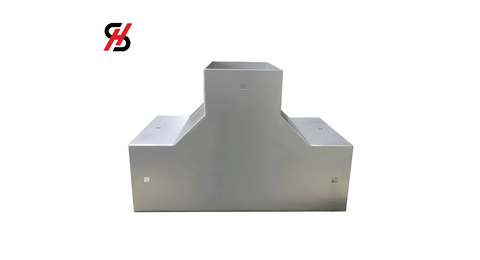

Our comprehensive services include laser cutting, deburring, bending, welding, tapping and drilling, rolling, lathe and milling, surface treatment, and outsourced processing services. We offer customized solutions to meet diverse design requirements, ensuring every part meets strict quality standards for reliable performance and excellent craftsmanship. See all Siang Hsing products—high‑precision metal enclosures, cabinets, frames, and functional components. AMADA fiber laser cutting + CNC bending + welding + finishing for reliable results.

Sheet Metal Processing Scope

Stainless Steel Sheet, Black Steel Sheet, Aluminum Sheet, Copper Sheet

Siang Hsing specializes in precision processing of stainless steel, black steel, aluminum, copper, other metals, meeting a wide range of structural and mechanical applications needs.

Our comprehensive services include laser cutting, deburring, bending, welding, tapping and drilling, rolling, lathe and milling, surface treatment, and outsourced processing services. We offer customized solutions to meet diverse design requirements, ensuring every part meets strict quality standards for reliable performance and excellent craftsmanship.

Sheet Metal Processing Scope

Sheet Metal Maximum Processing Size: 3050*1550mm

Sheet Metal Thickness Range:

● Stainless Steel: 0.5~16mm

● Black Steel: 1.2~25mm

● Aluminum: 1~12mm

● Copper: 1~8mm

Sheet Metal Processing Scope | Siang Hsing (SHPS)

Siang Hsing Precision Stamping Co., Ltd. is a local professional metal processing product manufacturer in Taiwan. Established in 2023, the founder has over 28 years of experience in precision machining, sheet metal processing, surface treatment, welding, laser cutting, workpiece assembly, and bending operations. Siang Hsing (SHPS) consistently meets the various quality requirements of its customers.

One-stop Sheet Metal Processing Scope - Siang Hsing (SHPS) delivers precise sheet metal fabrication through high-accuracy laser cutting, CNC bending, welding, and assembly. Our streamlined workflow ensures clean edges, accurate forming, and dependable quality for custom enclosures, brackets, frames, and industrial components across multiple industries.