Tapping and Drilling Process | AMADA Fiber-Laser & CNC Bending - Siang Hsing

Siang Hsing provides precise sheet metal tapping and drilling services, capable of creating accurate internal threads for various metals and hole sizes to ensure smooth screw fastening and structural stability.

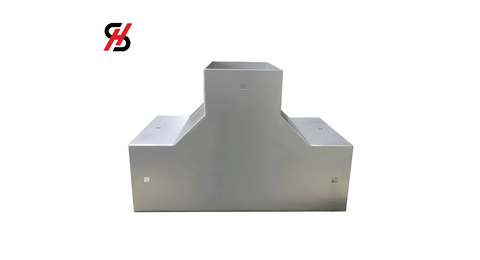

Whether for prototype samples or mass production, Siang Hsing delivers consistent quality and precise techniques to fulfill the needs for mechanical parts, structural components, and sheet metal products. Our integrated processing capabilities also enable seamless, one-stop manufacturing of finished products. See all Siang Hsing products—high‑precision metal enclosures, cabinets, frames, and functional components. AMADA fiber laser cutting + CNC bending + welding + finishing for reliable results.

Tapping and Drilling Process

Tapping, Drilling, Threaded Hole, Machining Services

Siang Hsing provides precise sheet metal tapping and drilling services, capable of creating accurate internal threads for various metals and hole sizes to ensure smooth screw fastening and structural stability.

Whether for prototype samples or mass production, Siang Hsing delivers consistent quality and precise techniques to fulfill the needs for mechanical parts, structural components, and sheet metal products. Our integrated processing capabilities also enable seamless, one-stop manufacturing of finished products.

Tapping and Drilling Process | Siang Hsing (SHPS)

Siang Hsing Precision Stamping Co., Ltd. is a local professional metal processing product manufacturer in Taiwan. Established in 2023, the founder has over 28 years of experience in precision machining, sheet metal processing, surface treatment, welding, laser cutting, workpiece assembly, and bending operations. Siang Hsing (SHPS) consistently meets the various quality requirements of its customers.

One-stop Tapping and Drilling Process - Siang Hsing (SHPS) delivers precise sheet metal fabrication through high-accuracy laser cutting, CNC bending, welding, and assembly. Our streamlined workflow ensures clean edges, accurate forming, and dependable quality for custom enclosures, brackets, frames, and industrial components across multiple industries.